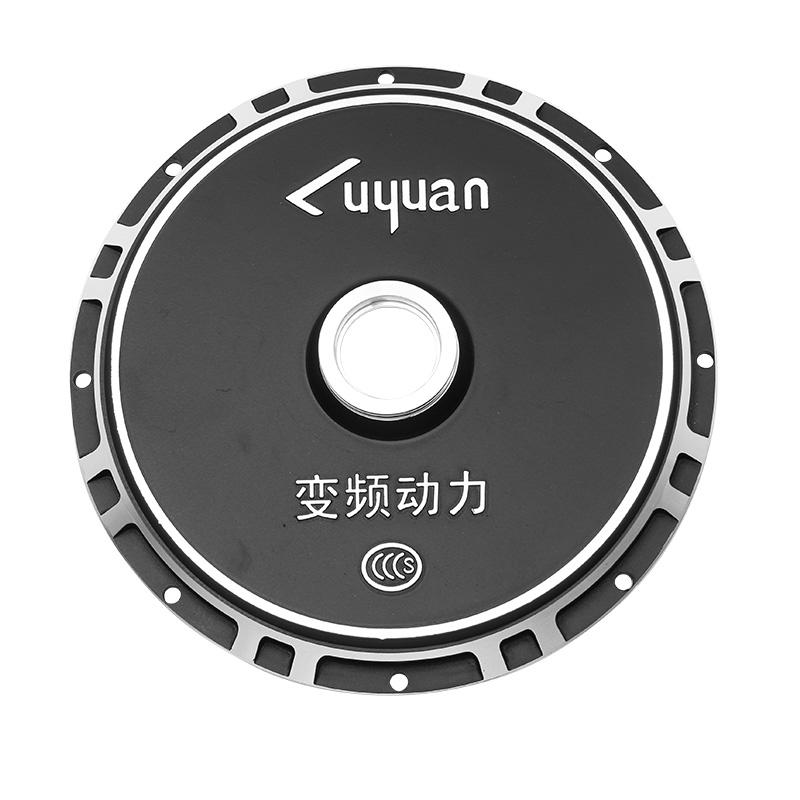

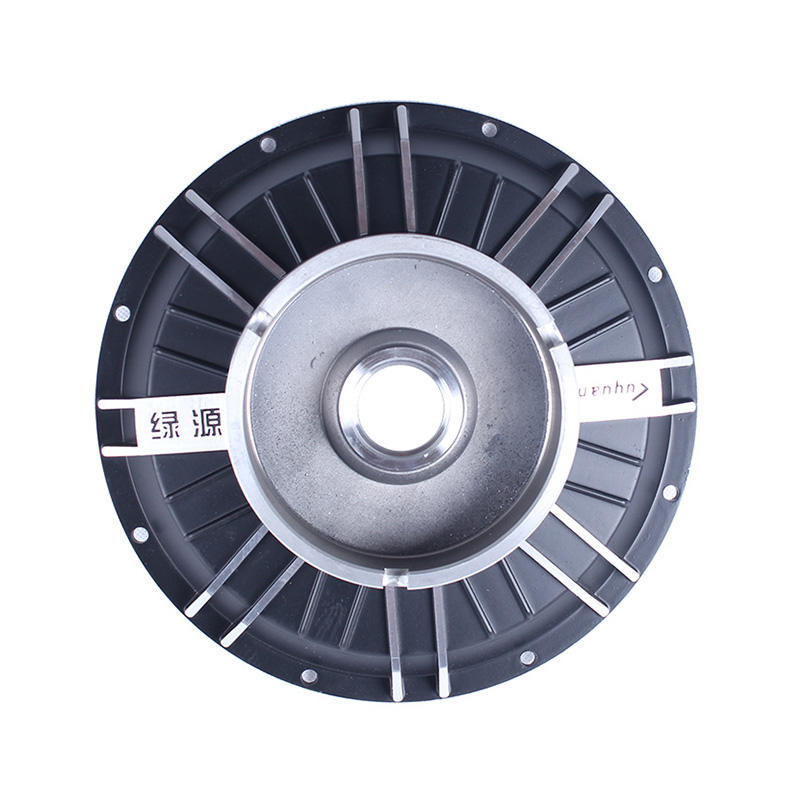

Aluminum die-casting parts for electric vehicles are parts made using the aluminum die-casting process for the production of electric vehicle components. The use of aluminum in EV components offers several advantages, including light weight, high strength and good thermal conductivity. Die casting allows the production of complex shapes with tight tolerances and high precision, making it ideal for the production of EV components such as battery housings, power electronics and motor assemblies. The die casting process also allows for high quality surface finishes, reducing the need for additional machining and finishing operations. By using aluminum die-cast parts, manufacturers can produce high-quality, lightweight and durable EV components that contribute to the overall efficiency and performance of the vehicle.

Product Benefits:

Lightweight: Aluminum is lighter than other metals, helping to reduce the overall weight of the vehicle and improve fuel efficiency.

High Strength: Aluminum die-cast parts have a high strength-to-weight ratio, making them suitable for high stress applications.

Corrosion resistance: Aluminum has corrosion resistance, which makes it ideal for use in harsh environments and helps extend the life of components.

Electrical conductivity: Aluminum is a good conductor of electricity, making it ideal for use in electrical components.

Recyclability: Aluminum is fully recyclable, making it an environmentally friendly choice for use in electric vehicles.

Cost-effective: Aluminum die-casting is a cost-effective manufacturing process that helps reduce the overall cost of the vehicle.

EN

EN English

English 中文简体

中文简体 Deutsch

Deutsch +86-13185140855

+86-13185140855