Specializing in the production and processing of various zinc, magnesium and aluminum alloy castings.

Founded in 1989, Zhejiang Wuxing Power Manufacturing Co., Ltd is a professional Aluminum Die Casting Accessories for Power Tools Manufacturers and OEM Aluminum Die Casting Accessories for Power Tools Factory with a registered capital of 5 million and an area of 15,000 square meters. We specialize in custom Aluminum Die Casting Accessories for Power Tools, and can develop and produce products according to the drawings or samples provided by customers, and we will conduct corresponding inspections after each process. For the final product, we will conduct 100% full inspection according to customer's requirements and international standards;

The company now has dozens of 200T-1000T die-casting machines, CNC machining centers, bench drills, multi-hole drills, tapping machines, shot blasting machines and three-coordinate measuring instruments and other production equipment and testing equipment. And has machining, CNC processing, punching, drilling, polishing, shot blasting, grinding, painting, electroplating and other processes. Professional equipment, mature technology, technology and high-quality technical team provide you with one-stop service from blank to spraying.

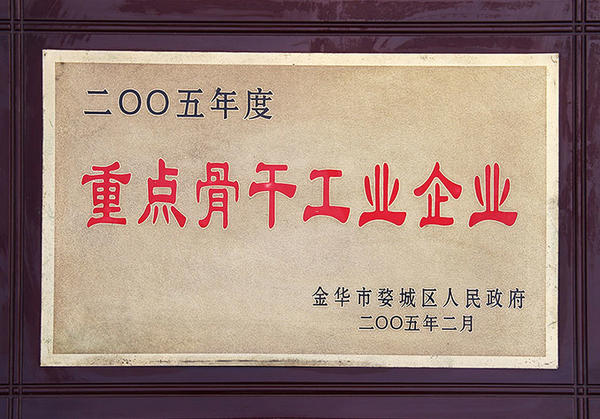

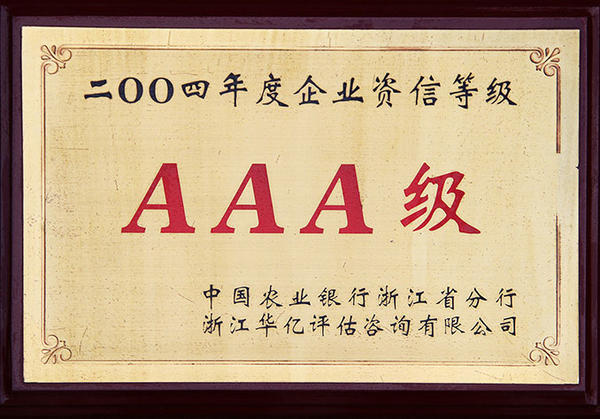

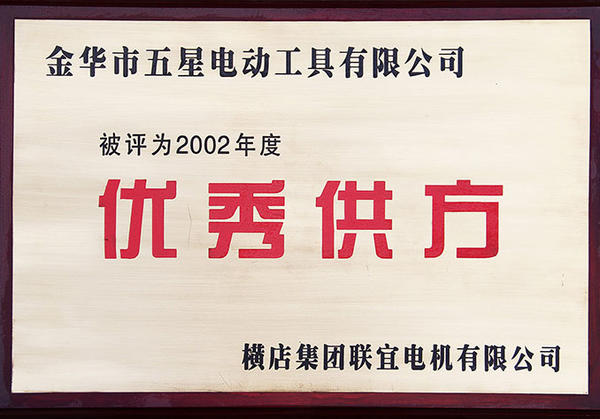

With its professional casting level and superb technical service, the company has won unanimous praise from users, and has won the trust and support of more and more customers. We have established long-term and stable friendly cooperative relations with Luyuan Electric Vehicle, Wanliyang, Crown, Hengdian Group and other enterprises. Customer satisfaction is our constant pursuit.

EN

EN English

English 中文简体

中文简体 Deutsch

Deutsch +86-13185140855

+86-13185140855